|

Gongyi Yulin Welding Material Co., Ltd

|

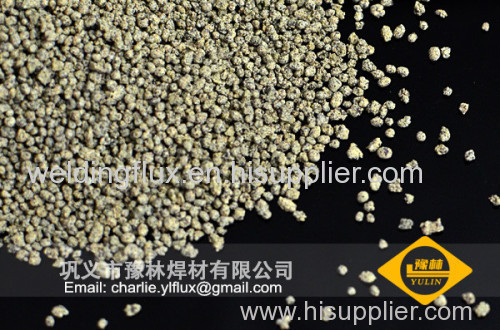

Yulin brand welding flux SJ301

| Price: | 400.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Welding flux SJ301 is used for pipes welding, structural steel welding, H & I beam welding.

Excellent mechanical properties and welding performance.

Name: Agglomerated submerged arc welding flux SJ301

AWS: AWS/ASME SFA-5.17 F6A0-EL8 F7A2-EM12K

SAW wires: EL8, EM12, EM12K, etc.

Power supply: DC (DCEP), AC

Basicity: 1.0 BIIW.

Grain size: 10-60 mesh (0.28-2.0mm)

Alloy transfer: Si, Mn alloying

Category: submerged arc welding mild steel & low-alloy steel

Industry: structural steel, pressure vessel, bridge building, ship building, pipeline, boilers, LPG tank, etc.

Description: neutral type calcium and silica based,

agglomerated flux. Excellent welding performance, easy slag removal.

Short slag, especially suitable for circumferential welding of small

diameter pipes. Also applicable for multi-pass welding, double sided

single pass welding, multiwire welding.

Package: damp-proof packing, 25kg/bag

Certification: ABS, CCS, LR

Chemical Composition of Flux (%)

| SiO₂+TiO₂ | CaO+MgO | Al₂O₃+MnO | CaF₂ | S | P |

| 25-35 | 20-30 | 20-30 | 5-15 | ≤0.03 | ≤0.08 |

Mechanical Properties of Deposit Metal

| Accompanied Wire |

Yield Strength ReH (δs) MPa |

Tensile Strength Rm (σb) MPa |

Elongation A (δ5) % | Charpy-V lmpact Test (J) | ||

| +20℃ | 0℃ | |||||

| EL8 | ≥360 | 420-550 | ≥22 | ≥70 | ≥50 | |

| EM12 | ≥420 | 500-650 | ≥22 | ≥70 | ≥50 | |

Attention:

1.

We get values in data sheets from tests carried out in accordance to

AWS and GB standard procedure. They only represent values we get under

those conditions. They are not to be taken as guarantees. As to welding,

individual test results may vary depending on experience &

technique, flux type, base metal, joint preparation,

flux preparation, ampere, voltage, etc.

2. If welding fluxes are stored in improper environment or influenced by

condensed moisture, anyway, they get damp, please dry them at 300-350℃ for 2 hours before usage.

3. Please clean the rust, oil, water on base metal before welding.

4. Add minumum 20% new flux when using

recovered flux to avoid welding defects and maintain welding performance

& mechanical properties.

5. Please control parameters properly, like preheat temperature, interpass temperature, cooling rate.